Conditions of use:

The highest medium temperature: 40 ° C

FH value of the conveyed medium: 5-9

Maximum liquid density: 1150 kg/m

Minimum submerged depth: 0.9m

Every second start interval time is not less than 10 minutes clamp

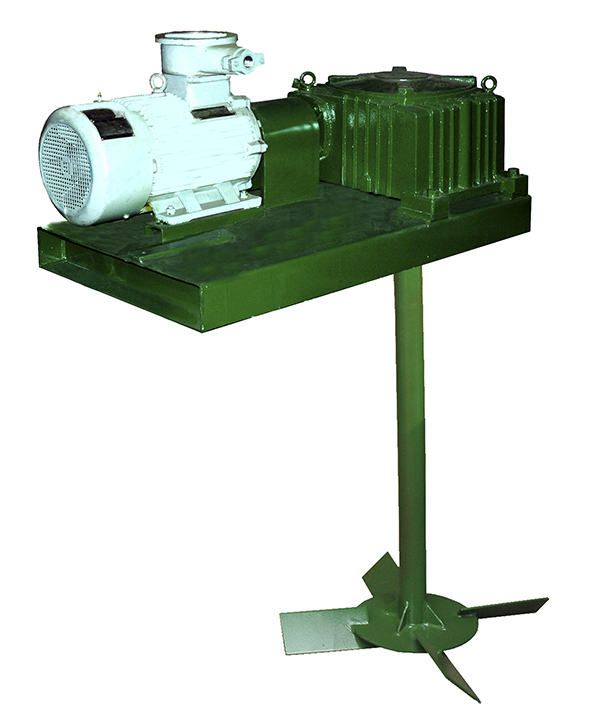

1, submersible Mud Agitator: composed of motor and pump head, the pump head is coaxial with the motor, using two mechanical seals. According to the need to set up in the submersible Mud Agitator with oil air leakage report monitoring, motor winding overheating protection and bearing temperature measurement protection and other functions.

2, control equipment: used for submersible mixer start, stop and operation monitoring, according to different user requirements can include control cabinet, terminal box, liquid level controller, etc., and is equipped with overload, phase failure, short circuit, water leakage, motor winding overtemperature, bearing overtemperature and other protection functions. For details, please refer to the random instruction manual of the control equipment.

Caution:

1、Check whether the selection of submersible Mud Agitator is correct, and whether the actual use conditions are consistent with the specified use conditions.

2、The protection of the agitator motor cable in the mud chamber has two types of hard steel tubes and metal hoses. Ensure that the tube connection is sealed.

3, with 0-500V megohmmeter, check the insulation resistance of the three cores of the main motor cable to ground shall not be less than 5 megohms, disable the megohmmeter to check the control cable to avoid damage to the electrical components inside the submersible mixer, and apply a multimeter to check the control cable line.

4. If the power supply capacity of the submersible mixer is far from the use of this, Kaozhi line loss, cable cross-sectional area should be increased,