Both are widely used screening equipment, but different methods and principles of operation also mean differences in throughput and types of screenable materials. This paper analyzes the difference between the roller mainsail and the vibrating mainsail from the following six aspects.

1. Different sowing methods

Vibrating screen and trommel screen belong to distribution equipment. According to different screening methods:

The

vibrating screen is distributed by the exciting force generated by the vibrator. It is a part of the vibrating screen and is often used in the round screen, wire screen, etc. for mining.

Trommel screen is another form of screening, the equipment does not vibrate, but the general motor and deceleration capacity rotate through roller bearings, the material rotates at high to low speed in the drum, sieved through the screen and successfully screened. , This is a rolling dropout a part of.

2. Different shape and structure

They vary in shape and are easy to tell apart.

Lightning rod: It is a cylinder with one or more layers or several screen sections to increase the screen size outside, generally larger, mainly the motor is lying on it, roller gear, grid, grid, grid, and seal should be added to the roller. Set the hatch to prevent it from deforming.

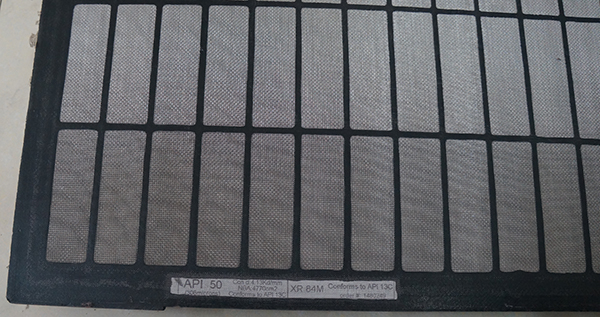

The vibrating screen is mainly composed of screen, screen, screen, vibrator, base, damping spring, bracket and so on.

Vertical vibrating screen: There are two motors at the bottom of the equipment, which can be divided into several stages.

Circular vibrating screen (also called uniaxial screen) has two types: suspension type and seat type.

Screen mesh and vibrating screen are usually composed of composite mesh or punched mesh, and its size is 6mm-8mm.

Third, everything works differently

roller shutter

The rollers are mounted on the frame at an angle. The motor-gearbox is connected to the rollers by couplings that allow them to move along their axis. After the material enters the drum unit, due to the inclination and rotation of the drum device, the material on the lightning arrester is turned over and swayed, and the corresponding material (product on the screen) is discharged through the rear exhaust pipe hole. The drum, the inferior material (product on the screen) is discharged through the exhaust pipe at the end of the drum.

Using the vibration lifting motor as the vibration source, the material moves in a straight line along the mesh, evenly passes through the lightning rod inlet, through the multi-layer mesh, and flows out from each individual outlet.

circular vibrating screen

The sieve is fixed on the sieve and supported by a spring suspension or bracket, and the main shaft bearing is installed on the sieve and rotates at high speed with the help of wheels. The eccentric spreading disc is installed on the main shaft, and with the rotation of the main shaft, centrifugal inertial force is generated, which produces vibration similar to the circular trajectory of the main sail.

Four different categories

According to the different number of screen layers, the screen mesh can be divided into independent, two-layer and three-layer vibrating grottoes. This vibrating grotto can also be divided into single, two, three and four layers according to the number of screens.

According to whether the screen station is connected with the bearing, it can be divided into axial screen and shaftless screen.

According to the movement trajectory of the mainsail surface, it can be divided into circular and linear screens, which are presented from above.

5. Development and application in various occasions

Roller screens are manufactured for long life and are designed for high volume use.

Linear vibrating screens produce very little usable material to screen fine gauges.

The circular vibrating screen has a large output and is suitable for large and medium-sized production lines.

Due to the different screening methods of vibrating screen and trommel screen, the materials they screen are also different:

(1) The more pebbles and the more sticky pebbles, because the vibration force of the vibrating grotto is stronger, and it is better to use the vibrating grotto.

(2) For dusty and fine-grained materials, which is a weak point of the vibrating screen, screening with a sieve will be more effective.

(3) Dry matter screening for vibration screening is not easy to block the channels, and the screening effect is better.

6. Different screening accuracy

The vibrating screen is composed of distribution equipment and is the vibration source, so the complete set of sieves has high precision.

The vibrating screen and the screen have their own working methods and screening principles, through which some raw materials can be screened, but different places and different material requirements must choose a suitable screening mechanism to achieve a good complete set of results.