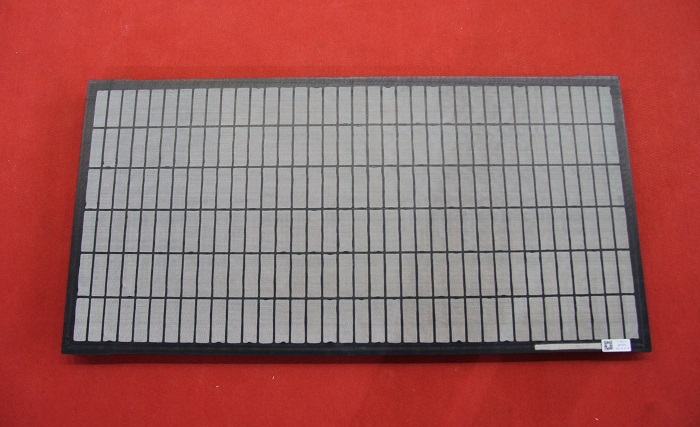

The iron frame vibrating screen is a commonly used oil vibrating screen, which is mainly composed of a steel frame and 2-3 layers of stainless steel screens closely connected on the frame. The frame is welded by high-strength square tube or flat steel, and is provided with multiple supporting reinforcing ribs, and the metal sheet can be glued to the frame with metal adhesive, or can be directly glued to the frame. The high-strength steel frame and support ribs form a solid whole with the moderately tensioned screen, which greatly improves the flow, strength and life of the screen. The grids of each grid layer are different, and accurate and reasonable matching makes the screening effect more detailed. The mesh fabric is divided into several independent fine mesh surfaces to prevent excessive expansion of local lesions. At the same time, it is equipped with a special rubber stopper to prevent damage, save time and reduce operating costs.

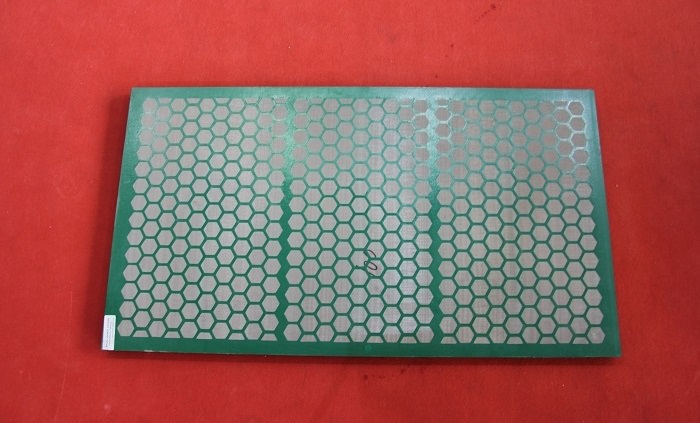

Polyurethane mesh gets its name because it is made of polyurethane raw material. It is a high molecular organic elastomer with high elastic modulus, large bearing capacity, high impact absorption strength, and is not easy to block pores during use. High wear resistance, high elasticity, high strength, high automatic cleaning force, greatly improve the screening and production efficiency. At the same time, due to its high wear resistance, its service life is several times or even dozens of times that of traditional metal screens, and it is the most wear-resistant and durable screen material today.

Stainless steel screens are often used for screening and filtration in acidic and alkaline environments, as well as mud screens in the petroleum industry and screens in the chemical fiber industry. The stainless steel vibrating screen is mainly composed of 201, 201, 302, 304, 304L, 316, etc., and has the characteristics of acid resistance, alkali resistance and rust resistance. At the same time, the stainless steel screen is resistant to high temperature oxidation and easy to form. The rated temperature of 304 stainless steel screen is 800℃, and the rated temperature of 310S stainless steel screen can reach 1150℃. .

The above are 4 common composite vibrating screens of vibrating screen, iron frame screen and polyurethane stainless steel screen. In addition to these four types of screens, other classification criteria can also be used. category.